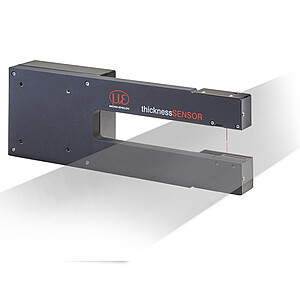

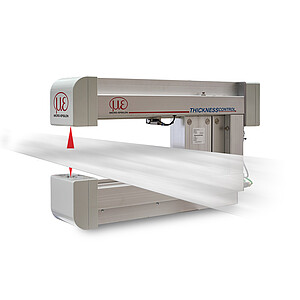

Misurazione in linea senza contatto dello spessore del profilo di materiale di rivestimento interno (spessore da 1 mm a 18 mm)

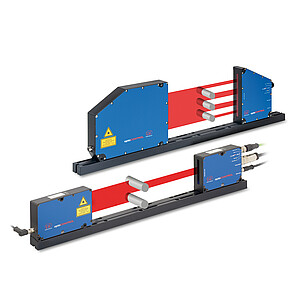

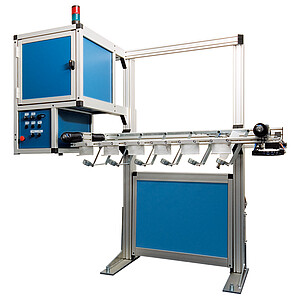

Nella produzione dei rivestimenti interni, i sistemi della famiglia thicknessCONTROL TIP misurano il profilo di spessore del materiale immediatamente a valle della calandra. L’alta precisione dei sistemi ottici di misurazione senza contatto assicura una qualità e una sicurezza ottimali del prodotto realizzato. In questa applicazione possono essere utilizzati anche i dispositivi della serie thicknessCONTROL RTP.

Vantaggi:

- Qualità sempre elevata dei prodotti con un impiego ottimizzato delle materie prime

- Regolazione rapida durante l'accostamento o il cambio di prodotto grazie a velocità di traslazione trasversale adattive e alla misurazione ultra dinamica

- Assenza di costi per l'acquisto di una protezione contro le radiazioni, ecc. poiché non vi sono isotopi o raggi X. Misurazione senza usura invece del tempo di dimezzamento dei campioni radiometrici

- Stabilità in temperatura elevatissima grazie alla calibratura in situ e agli elementi di compensazione

- Interfacce adattabili alle esigenze del singolo cliente

Parametri del materiale:

- Larghezza del materiale da 200mm a 3800mm

- Avanzamento del materiale fino a 25 m/min

- Max. temperatura superficiale del materiale ammessa: 100° C

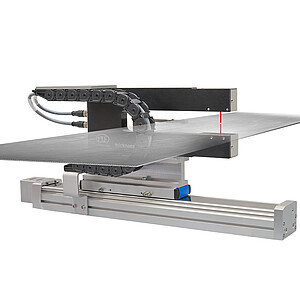

I prodotti della famiglia TIP sono realizzati con telai a O e C e dotati di sensori ottici. Le variazioni termiche dei meccanismi di misurazione vengono rilevate con sensori di spostamento e temperatura supplementari e compensati per mezzo di algoritmi. Per questa applicazione possono essere utilizzati anche i sistemi della serie RTP come soluzioni low cost.

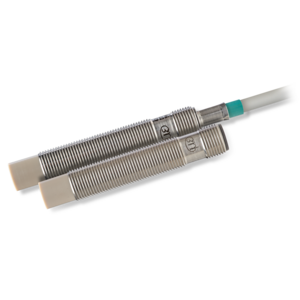

The system TIP 8301.EO operates according to a combination principle consisting of a thru-beam sensor, an eddy current sensor and a measuring roller. The eddy current sensor and the thru-beam sensor are applied on an innovative measuring clamp. Since the sensor measures the distance from the clamp to the roller, the lower side of the material is detected. Since the sensor performance is specially aligned with the measuring task a huge measuring gap is possible while offering highest precision. The thru-beam sensor detects the upper side of the material. The thickness of the target is the difference between the two signals. The measuring clamp is equipped with a pneumatically cleaning mechanism and therefore ideal for the application in harsh environment.

Special features:

- Linearity ±5µm

- Measuring gap 15mm

- Dimensional thickness measurement, independent from material components

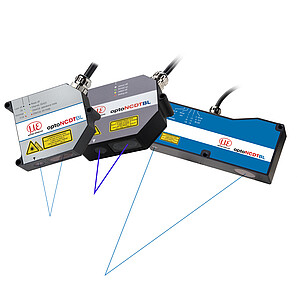

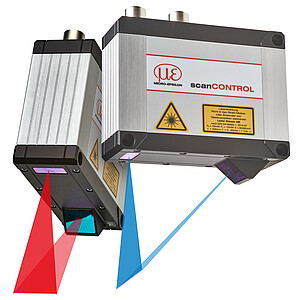

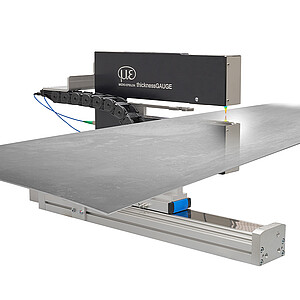

The TIP 8301.CT is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The O-frame mechanics of the system dispose of a compensation frame which does not vary with temperature and which is used in order to avoid temperature fluctuations of the measuring frame using further sensors.

Special features:

- Linearity ±5µm

- Measuring gap 18mm

- Dimensional thickness measurement, independent from material components

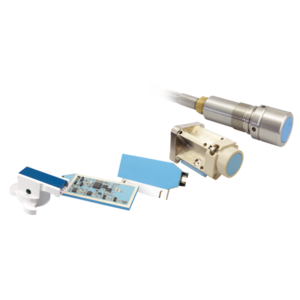

The TIP 8301.ET is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. The system is designed as O-frame, both sensors detect the thickness according to the differential method. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The triangulation sensor applied on the upper side is combined with an eddy current sensor which monitors the distance of the two optical measuring sensors while allowing a software-technical compensation of temperature-induced changes of the measuring gap. Additionally, the compensation sensor is applied according to a special alignment with the measuring task in order to ensure both, a huge measuring gap and highest precision.

Special features:

- Linearity ±10µm

- Measuring gap 20mm

- Dimensional thickness measurement, independent from material components

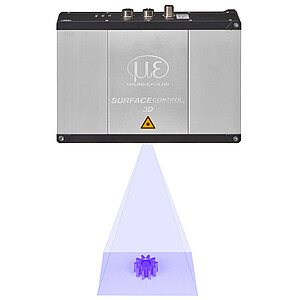

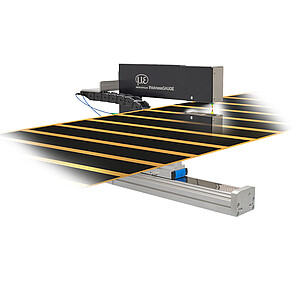

The RTP 8302.T is based on the laser triangulation sensors and therefore ensures the measurement being independently from material constants. In order to ensure highest precision, the laser beams of the sensors are accurately adjusted during the production process using optoelectronic tools which have been specially developed. The system is ideal for monitoring high-dynamically processes due to its high measuring rate. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Special features:

- Linearity from ±5µm

- Measuring ranges up to 20mm

- Immersion depth from 50° to 1,000mm

- Special sizes on request

- Measuring rate to 20kHz

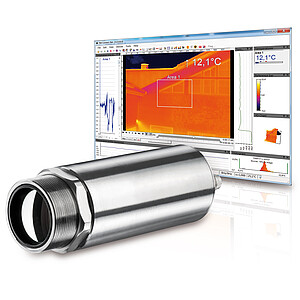

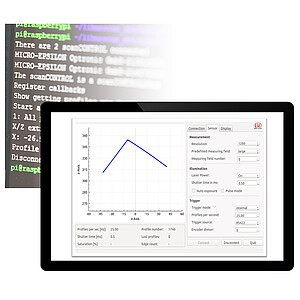

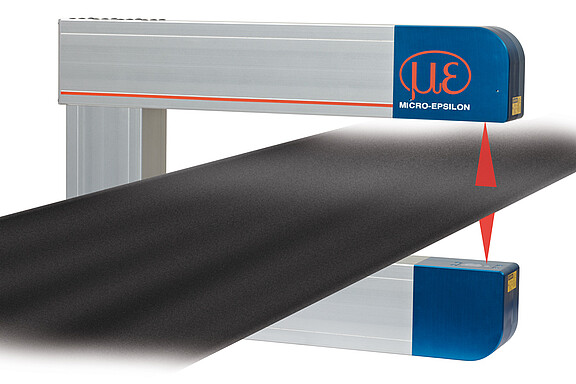

The RTP 8302.LLT is based on the laser line triangulation sensors and therefore ensures the measurement being independently from surface characteristics of the target material. Combined to point sensors, the system offers more precision in the case of gap width. The C-frame mechanics of the system disposes of an automated in-situ calibration in order to avoid interferences caused by temperature.

Special features:

- Linearity ±10µm, 40mm measuring range

- Gap width 300mm

- Immersion depth from 50° to 1,000mm

- Special sizes on request

- Measuring rate to 2kHz