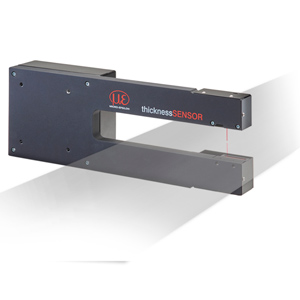

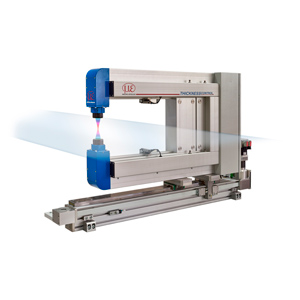

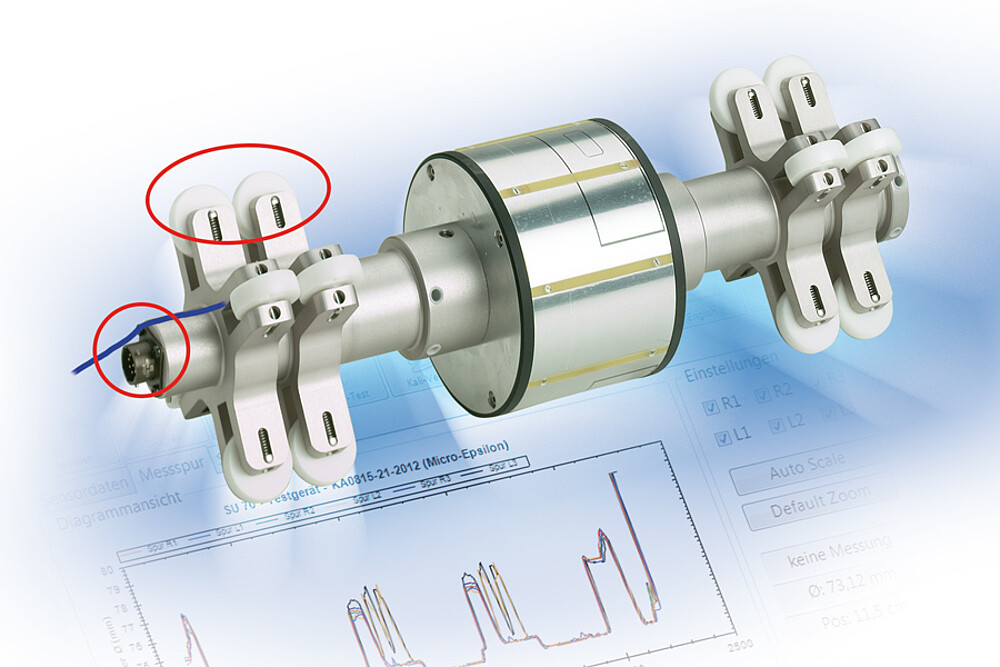

Ispezione del diametro interno di corpi di estrusori

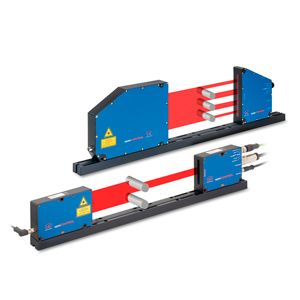

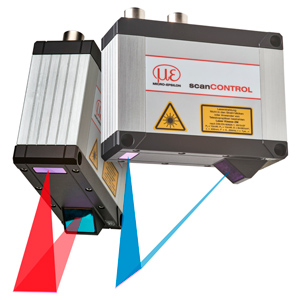

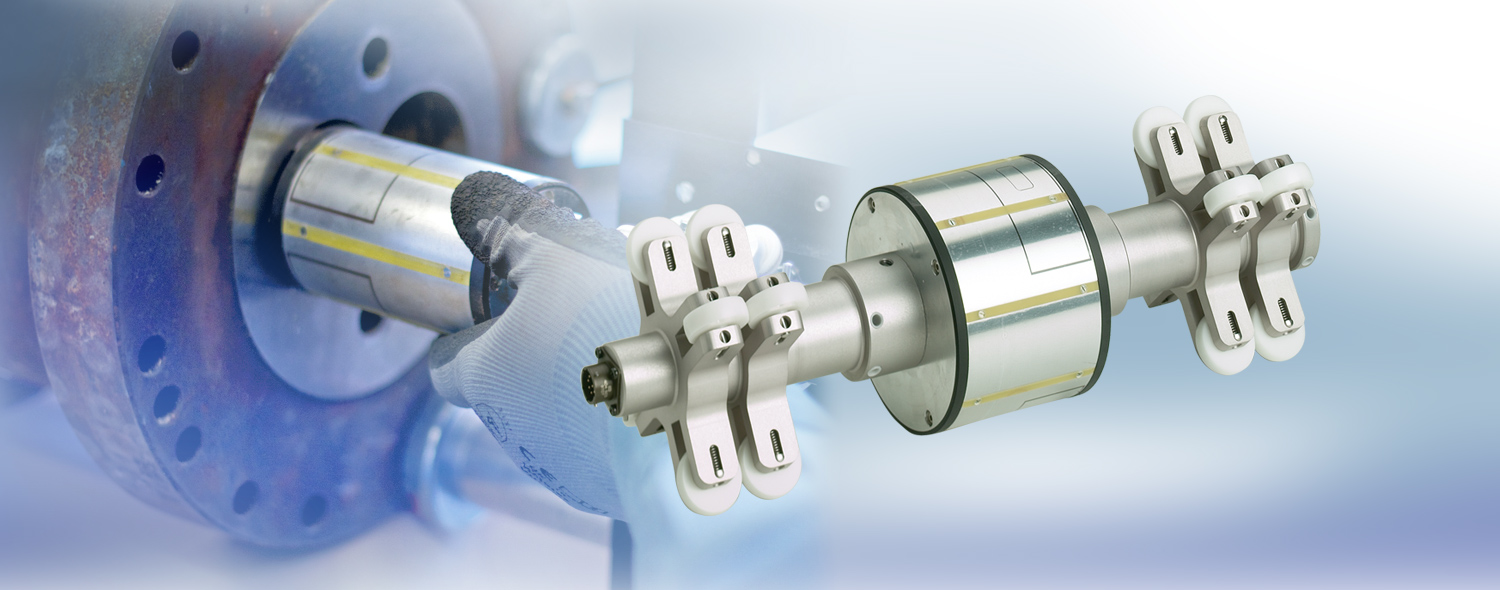

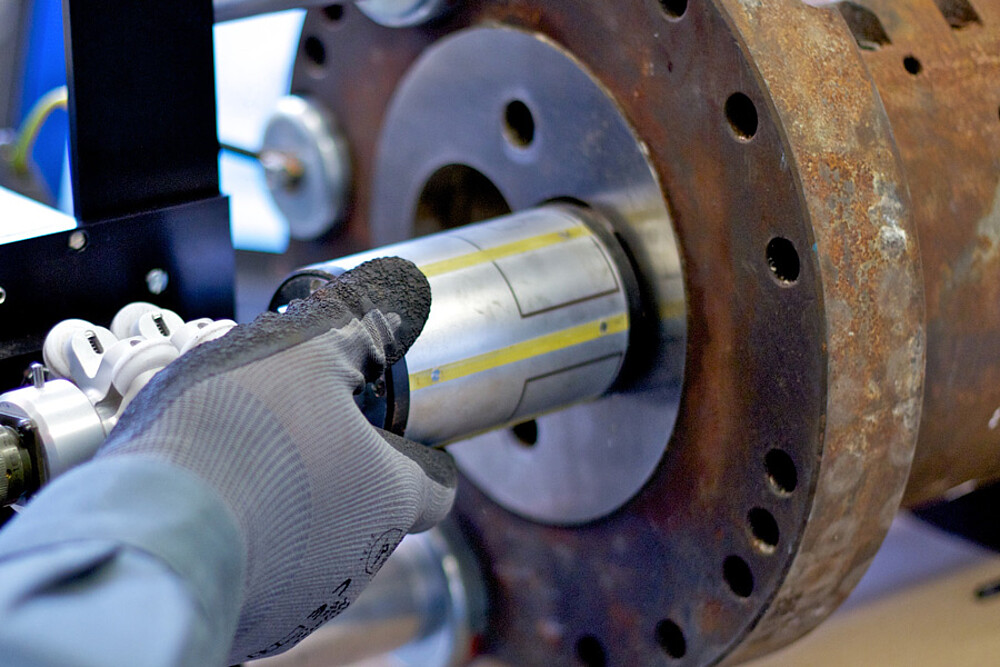

Il sistema sensore idiamCONTROL msura con precisione il diametro interno di fori come ad esempio estrusori per determinarne l'usura. L'idiamCONTROL viene guidato nel foro e determina il diametro del foro durante l'estrusione. Scostamenti di tolleranza basati sull'usura vengono visualizzati automaticamente e possono essere emessi via USB.

Advantages

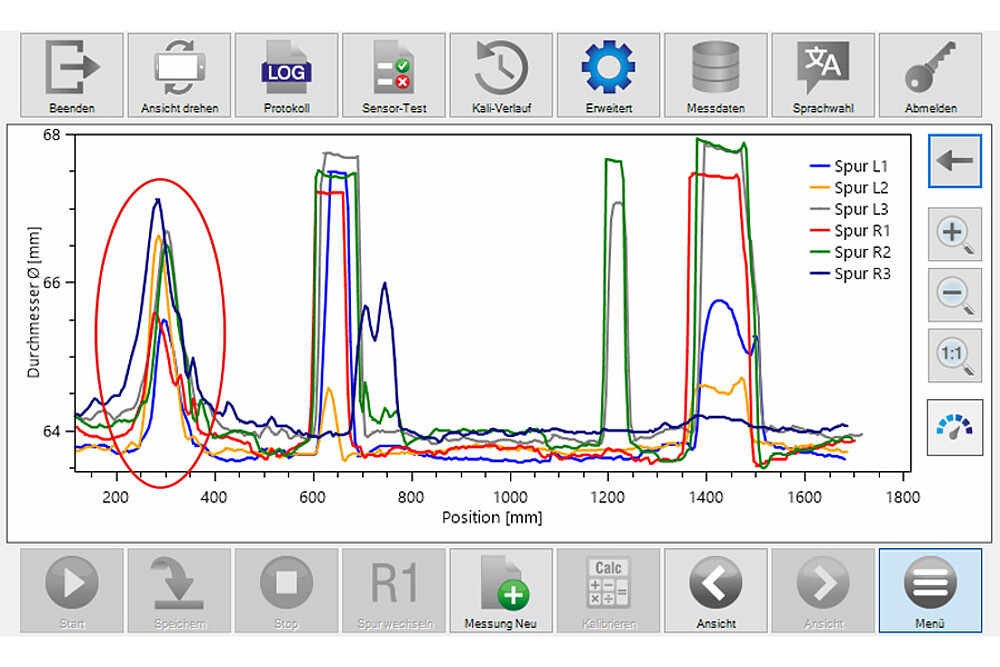

- Touchscreen with user-friendly software for fast evaluation directly next to the extruder

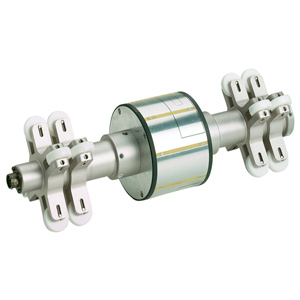

- Reliable measurement on up to 6 tracks

- Suitable for numerous extruder barrel dimensions from 32 to 180 mm diameter

- Diameter is directly displayed

- Automatic evaluation function via tolerance specifications

- USB interface for data output and logging

- Integrated function test for inspecting the condition of the measuring system

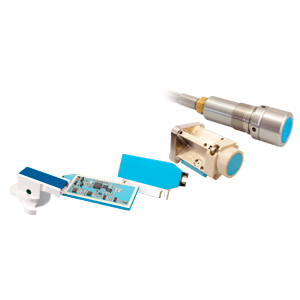

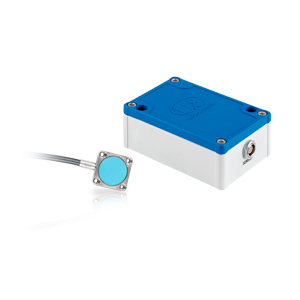

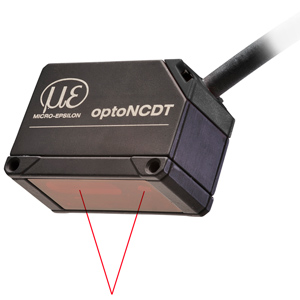

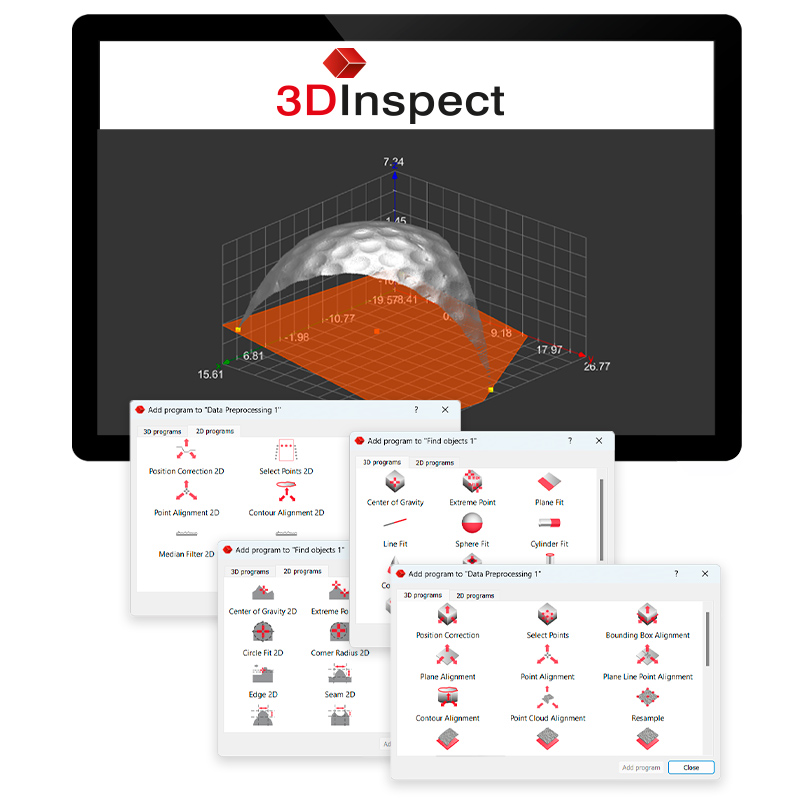

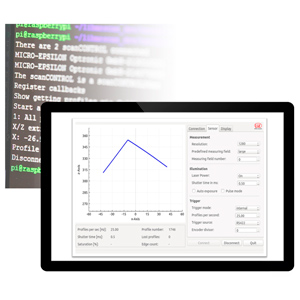

Operating principle

The idiamCONTROL works with integrated capacitive displacement sensors. These measure the actual bore diameter over the whole length of the process part. As the axial sensor position is detected as well using a cable-length measuring system, deviations in diameter can be found quickly and reliably. In doing so, each sensor position is related to a diameter in the longitudinal axis of the bore hole. As a result, the diameter length profiles are provided in six tracks and with a spatial resolution of 1 mm. The wear is calculated from the respective diameter values using the evaluation software.