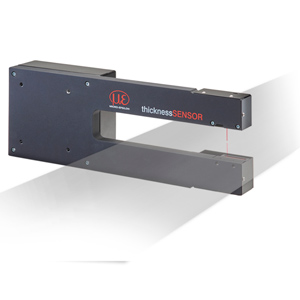

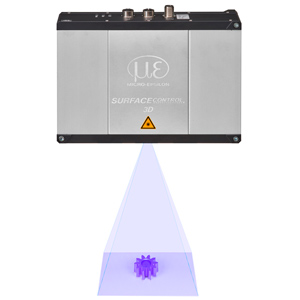

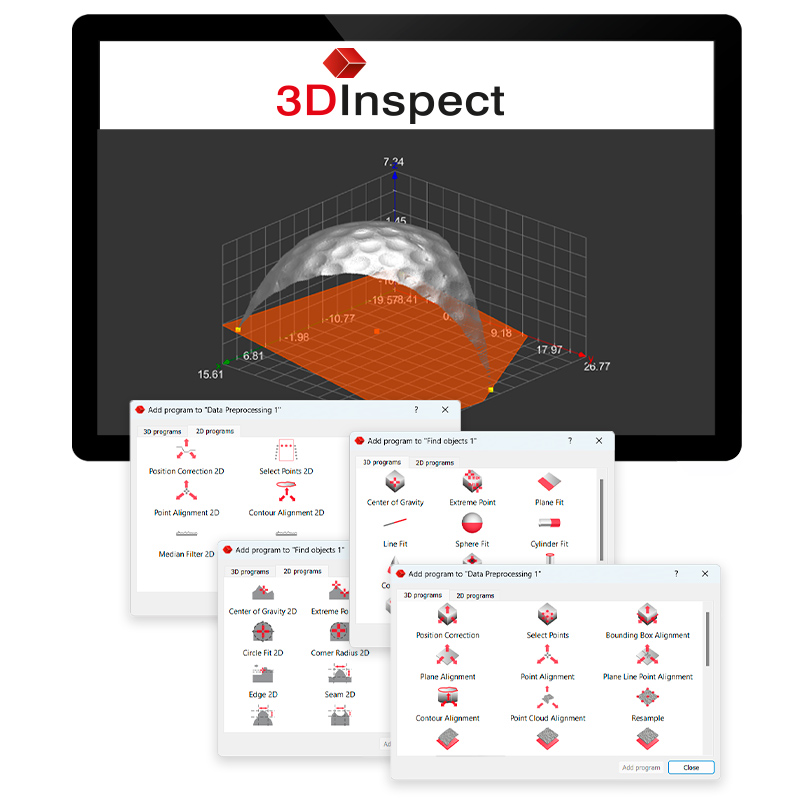

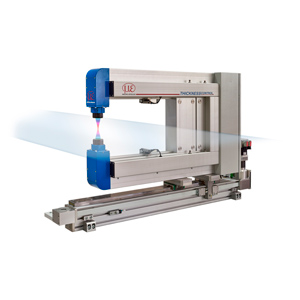

3DInspect is a user-friendly software tool for all Micro-Epsilon 3D sensors. Version 3.0 of the software is now available. With the functional extension for surface inspection, it is possible to detect deviations from a homogeneous surface. This means that 3DInspect can be used for digital quality control. This is performed according to predefined criteria, eliminating subjective influences which makes it possible to detect defects at an early stage.

Shape subtraction

Various shape subtraction functions are available. With the “Trend removal” function, small defects such as dents, bumps, unevenness or structures can be made visible quickly and reliably. The “Digital Stone,” or digital smoothing, allows inspections of production parts to be carried out with high precision. The Digital Stone simulates a whetstone used in car body construction to ensure homogeneous surfaces on body shells. Teaching a “Digital Master” enables the target state to be compared with the actual state. One or more OK parts are merged into a master file. The components to be tested can then be compared with the stored master file.

Further innovations

Another useful feature is the sorting and counting of elevations and depressions. This is advantageous for automatic pin detection, for example, as pin lengths within a defined range can be assessed as OK/NOK.

The most important new features at a glance:

- Trend Removal, Digital Stone and Digital Master for surface inspection

- Defect detection with sorting and counting

- Alignment of the 3D point cloud

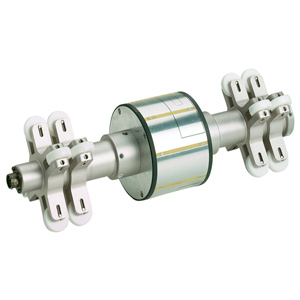

- Cylinder and sphere processing